The automotive landscape is changing rapidly. GaN Systems CEO Jim Witham spoke with AAC about the unique challenges of efficient power in automotive applications and how autonomous vehicles represent a convergence of major trends across the industry.

The term "mobility" has taken on a new significance in recent months and years, extending beyond the concept of moving from point A to point B. From the halls of CES where "mobility as a service" reigned supreme to the multi-billion dollar investments in developing autonomous vehicles over the past several years, mobility has become an important concept to the electronics industry.

While this increased attention on mobility has naturally resulted in a more intense focus on automotive applications, it turns out that many major trends in the industry are converging in this sphere, including data centers, renewables, and new methods of charging electric systems.

![]()

Toyota president Akio Toyoda at unveiling the e-Palette concept for mobility-as-a-service at CES 2018

GaN Systems CEO Jim Witham believes that a big portion of the evolution of electric vehicles and autonomous vehicles (EVs and AVs) will hinge on higher levels of efficiency. From his perspective, achieving this efficiency will require the use of GaN, or gallium nitride, a semiconductor that's been posed as an alternative to silicon and can allow for smaller, lighter power systems.

In a

recent trio of videos, Witham discusses the concept of mobility, EVs, and AVs with Uwe Higgin of BMW i Ventures, a venture capitalist group for incubating innovative technologies, a program in which GaN Systems participates.

Witham spoke with AAC to expand that conversation and lay out how EVs and AVs are more than just a particularly progressive portion of the automotive industry. EVs and AVs represent a new era in electronics, weaving together several industry trends that have been developing for years—an era in which Witham believes GaN will be crucial.

![]()

Jim Witham, CEO of GaN System

The Power Electronics Revolution

"We're in the midst of a revolution happening in power electronics," Witham begins. From the rise of the internet and the availability of affordable memory to the surge in mobile computing devices, the technological landscape has been changing quickly (and sometimes drastically) year over year. According to Witham, the two biggest areas that have grown due to these changes have been the development of data centers (particularly due to a rise online activity spurred by an expanding IoT) and the electric vehicle.

For someone like Witham, whose business deals intensively with power systems and their efficiencies, it's not hard to see how these particular trends are tied closely to power. But, he says, the scope of the issue of efficiency goes beyond the challenges of creating an effective power source. "[Efficiency] means you've got to be efficient with your energy and how it's used. But it also means you've got to be efficient with your materials—your copper and your aluminum and your printed circuit boards. You want to make them as small as possible so you minimize the amounts of materials. When you get down to it, it's all about circuits."

GaN Systems has built a reputation off of the idea that gallium nitride transistors are going to be instrumental in increasing efficiencies for power applications. Over the last several years, GaN has been gaining traction and, in some ways, threatening silicon's dominance in the industry. Especially in the last year or two, it seems that major corporations like Texas Instruments, Analog Devices, Dialog Semiconductor, Qualcomm, and others have been investing in this alternative semiconductor and releasing GaN components and modules.

Current applications for GaN are wide-reaching. It's been noted for its results as a semiconductor used for RF applications, including RF power amplifiers. It's also made possible things like 99% efficient inverter power stage designs.

Witham believes that GaN will be key for many upcoming trends and applications. "...with GaN transistors, you can make things that are four times smaller, four times lighter in weight, four times less energy as heat. They can make the overall system cost cheaper because of that. It's really a driving force for providing the vision for those things that are changing in our society."

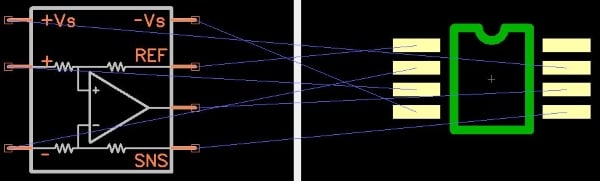

![]()

An example of a GaN transistor. Image courtesy of GaN Systems.

One of those society-changing concepts is how the automotive industry is rapidly evolving, especially in its move towards electrification and autonomous vehicles.

The Changing Landscape of Automotive Applications

In a general sense, vehicles are getting more high-tech. This is perhaps an unsurprising development as even refrigerators and toasters are becoming advanced enough to require cybersecurity measures. Tech companies, then, often view automotive as an important vertical for product development.

Witham says that GaN Systems, for their part, has viewed automotive as a basic building block in their company's focus for years: "We segment the market into four areas. One is consumer, one is data center, one is industrial, and the fourth is automotive or transportation." Transportation as a concept can, of course, include "everything from satellites to scooters, drones, forklifts, e-bikes. You name it. If it moves, people want to have lightweight power electronics in it—so it really cuts across all the venues, not just cars."

The real focus for transportation in recent years, however, is indisputably cars. Companies around the globe have been investing in technologies such as machine learning algorithms, longer-lived battery designs, and LiDAR sensors, all with automotive in mind. "You see it in places like the Consumer Electronics Show in Las Vegas, which used to be about TVs and computers but is now the biggest car show in the world."

![]()

A MobilEye display at CES 2018 shows off sensor innovations for automotive applications.

But while it may not seem extraordinary for a semiconductor company to consider automotive a major vertical, it's worth considering that automakers may not be quite as prepared to make technology a major part of their overall strategy. Automakers have largely enjoyed a relatively stable demand for their products. In recent years, however, Witham has noted that the tech industry has been placing increasing pressure on these automakers as technology companies inch further into the automotive space.

On one hand, more advanced technologies in cars have buoyed automakers with more attractive features to build into their products. On the other hand, the life cycle of the typical vehicle is much longer than that of the typical smartphone. With computing systems increasingly appearing in vehicles, it seems inevitable that industry-wide shifts will need to occur to allow automakers to keep up.

When asked if he thought the automakers will need to adjust lifecycles to keep pace with innovations in tech, Witham said, "I think they have to. I think they realize it. It has a lot to do with the non-car companies that are getting into this marketplace: the Googles and the Apples and the people like that who are used to these fast product cycles and fast turnarounds. They've flipped the whole model upside down. So the automotive companies know they have to react or they could out-innovated by the other guys. If they're on a five-year design cycle and the other guys are on a three-year design cycle...Wow, that's two and a half models out in the same time period. That's not good."

"The automotive companies know they have to react or they could be out-innovated by the other guys."

Of course, it isn't a simple matter of technology easily slipping into the automotive realm. Automotive applications face several unique challenges, including rapidly changing usability expectations and starkly unchanging safety expectations.

More Tech, Same Form Factor: Expectations for Electric and Autonomous Vehicles

While it may not necessarily look it on the outside, a high-end car released today is markedly different from one released 20 years ago. The concept that a vehicle can connect wirelessly to a smartphone is no longer a novelty but rather an expectation. Now there may also be expectations for a backup camera with predictive guidance, lane sensing and correction, capacitive touch-enabled infotainment consoles, and a whole host of other integrations of technologies that are just becoming common in consumer items.

All of these "bells and whistles" require power, making efficiency and power conversion more important than ever.

"It's only going to get more so, right?" Witham quips. "Those [features] are all kind of new things that you have got to charge. You've got to provide power for those things. They all have to go into a car but we don't want our power shape to grow. We have a basic shape. There's an SUV shape and there's a sedan shape and there's an economy car shape. They define what's put on the road. You can't grow that. But all the other stuff has to get smaller in order to be able to put more in there. I don't ever get to the point of "it's small enough" in the automotive world. We always want to strive for an extra cubic inch because that can be used somewhere else."

![]()

BMW's ConnectedDrive is an example of inter-device connectivity. Image used courtesy of BMW.

Despite the fact that cars provide such large form factors, space is still prime real estate when it comes to the size of electronics. At present, this sets automotive apart from other applications where "small enough" is still an important concept.

"A big marketplaces for us is solar renewable energy. It's kind of like a panel is a certain size and, once the electronics get small enough, it really doesn't matter anymore because you can stick them under the panel and so added shrinkage doesn't really help. Not so in the automotive industry. Keep striving for zero."

Safety and Reliability

So what sets automotive apart from other applications when it specifically comes to power?

"Probably the biggest difference is the reliability and quality," says Witham. "When we make and design transistors for the automotive market, we make things that can handle higher temperatures, more extreme cycles, higher voltages, higher current. We do this because we've supplied to the automotive industry before and we know that when the components last longer, then the subsystems last longer and the cars last longer themselves. When I first drove a car, cars broke a lot more than they do today. I'm pretty impressed with how mine, my family's, or my friends' cars last and how little they need to be repaired today compared to the old days. It's because, bottom line, the components are built to be really high quality and more reliable. We see that in spades with the automotive industry and with the amounts of testing we do and the amount of scrutiny we get into with our customers."

Reliability is also a major pain point when it comes to both AVs and EVs.

"For EVs, it's just standard automotive. People expect their cars to last for ten years and drive hundreds of thousands of miles and you've got to continue to do that with an EV just like you did with an internal combustion engine," says Witham.

But he doesn't necessarily see this expectation as a negative.

"There's always a drive for smaller, lighter, and more efficient. We're going to push up the efficiency higher and higher. By driving that efficiency up, you get really huge changes for the car because you can take that energy and instead of wasting it as heat, you can drive the car further. Or you can take batteries out of the car because batteries are heavy and expensive... When you don't burn up the energy as heat and you utilize it usefully, then you can also reduce the cooling system. If we can take three quarters of the wasted heat and put that back into useful energy and only have one quarter left, we can make the cooling system one quarter the size and that has these added benefits. So driving up the efficiency higher and higher gives us longer-distance cars, fewer batteries in the car, and smaller cooling systems which all make for a better vehicle."

Tying Trends Together for Sustainable Autonomous Vehicles

In March, GaN Systems showcased several demos at APEC, including applications related to renewables (such as solar), EVs, and data centers. As it turns out, all of these topics are important for autonomous vehicles.

Those same companies that are investigating entering the automotive sphere have been vastly expanding their data centers. The amount of data processing and storage necessary to support millions of autonomous vehicles is staggering. In broad terms, data must be gathered from sensors and systems in a vehicle, processed, run through decision-making programs, and then fed back to the car's systems to execute actions. While some of this processing must necessarily be done in the car, itself, sending data back to company data centers is important for exposing machine learning algorithms to the datasets that will allow them to make better driving decisions.

In 2016, Intel claimed at CES that a single autonomous vehicle could require

four terabytes of data per day. This makes data center efficiency important to a sustainable future for autonomous vehicles; according to Witham, companies like Google but also automakers like BMW are expanding their data centers.

But efficiency issues also include conversations about renewable resources.

"I had an 'aha' moment when I was visiting a couple of other companies and we were talking about CO

2 emissions," says Witham. "EVs don't make any sense at all if you're going to make your electricity using coal and oil. You've got to have wind and solar and hydro in order to make the electricity to power those electric vehicles, to power those data centers, and to crunch the data. If you tie all of those together, it really makes a great story of the future. If you don't and any one of those breaks down, the whole vision breaks down. These are all interrelated concepts and I feel like GaN Systems is doing its little part to make all the pieces happen and make the step forward for mankind in the power industry."

These power issues can have far-reaching effects on everyday life. Witham thinks of mobility as an important issue for social responsibility. A huge portion of our lives are spent in transit, he argues, and the repercussions of making the power systems behind transportation more efficient and available are huge.

"I think how we use our cars can be socially responsible. There's this huge gain to be had for society. We make the transistors that make not only the electric vehicle go but also a lot of the sensors and compute power that go with an autonomous vehicle. We can play a pretty big role in making that happen and making the assets more useful and making the time more useful to the people and the goods that are in front of us."

Jim and Uwe have been releasing a series of articles on the topics of EVs and autonomous vehicles to accompany their video trio. You can see the most recent article

here.

You can watch the first part of Jim's conversation with Uwe below: